联系人:陈攀

电话:0371-60900389

手机:13526538098

客服QQ:669468858

邮箱:panchen@hxabrasive.com

地址:河南郑州荥阳市高村工业园

| Hardness: HV/维氏硬度 | 2840-3320kg/mm2 |

| Hardness: Mohs/莫氏硬度 | 9.2-9.3 |

| Specific Gravity/比重 | 3.2-3.45 g/cm3 |

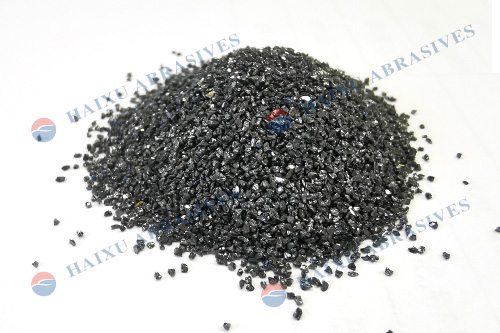

| Particle Shape/颗粒形态 | Fine powder/细小粉末 |

| Color/颜色 | Black/黑色 |

| Bulk density(LPD)/堆积密度 | 1.46-1.56 g/cm3 |

| Crystal shape/晶型 | Hexagonal/六方晶型= |

| Melting Point/熔点 | dissociated at about 2300°C/2300°C游离 |

| Maximum service temperature/使用温度上限 | 1900°C |

| Thermal conductivity/导热系数 | 70-130W/M·K |

| Thermal expansion coefficient/热膨胀系数 | 3.9-4.5 x10-6 /°C (0-1600°C) |

| Chemical Item/化学成分 | Guarantee Value/保证值(%) | Typical Value/典型值(%) |

| SiC/碳化硅 | ≥98.5% | 98.79 |

| Free C/游离碳 | ≤0.20 | 0.12 |

| Fe2O3/三氧化二铁 | ≤0.20 | 0.15 |

| Grit粒度 | Mesh#目数 | Mesh size(um)目数尺寸 | Weight Standard(%)重量占比 | Typical Value(%) 典型值 |

| Coarsest Grit最粗粒 | +18 | 1000 | 0 | 0 |

| Coarse Grit粗粒 | +25 | 710 | Max. 25 | 7.1 |

| Basic Grit基本粒 | +30 | 600 | Min. 45 | 46.5 |

| Mixed Grit混合粒 | +30 +35 | 600 500 | Min. 65 | 89.3 |

| Fine Grit细粒 | -40 | 425 | Max. 3 | 0.8 |

Copyright (©) 2021 郑州市海旭磨料有限公司 版权所有 地址:河南郑州荥阳市高村工业园 备案号:豫ICP备16034965号 XML地图